|

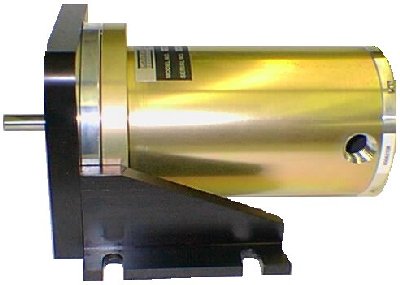

CC450-AE ABSOLUTE ENCODER |

|

The CC450-AE Absolute Encoder is used as a position feedback device where absolute measurement is required. It is a rugged electrical device and should be transformer coupled to the control system to avoid any induced noise via control common. APPLICATION The 450-AE Absolute Encoder is designed for use as a positioning feedback device in mill duty environments. Among its features are:

|

ELECTRICAL SPECIFICATIONS

| Code | 10 Bit Gray Code 10 Bit Natural Binary |

| Supply Voltage | 12-15 VDC |

| Supply Current | 200mA Max |

| Output Voltage | (TTL) 12 VDC |

| Operating Temperature | 0° to 70° C |

| Housing | NEMA 13 Material-6061 Anodized Aluminum Seal - O - Ring |

| Fastners | 303 Stainless Steel |

Shaft Size |

0.4998" (+.0000,

-.0005) 316 Stainless Steel 1/8" Keyway |

| Shaft Seal | Teflon Graphite |

| Moment of Inertia | 1550g/ cm2 |

| Bearing Life | 2 x 108 Revs at rated shaft loading |

Shaft Torque |

0.5 to 1.0 oz

- in w/o seal 1.0 to 2.0 oz - in w/ seal |

| Shaft Runout | 0.0005 T.I.R. |

| Speed | 700RPM, with shaft seal before gearing |

| Weight | 12 lb. |

| EXAMPLE: CC450AE-10G-200:1-FM-C | ||||||||

| SPECIFICATIONS | ||||||||

| 450AE | 10G | 200:1 | FM | C | ||||

| MODEL | 1 | 2 | 3 | 4 | ||||

MODEL =

CC450AE = BASIC

(Mill Duty) DESIGN

4 = OUTPUT TERMINATION |

PRODUCT DIMENSIONS

Dimensions = Inches

(mm)

Foot Mounts, Flange Mounts, Face Mounts, etc.